Biosecurity has never been more important to the UK pig industry. We summarise key advice on maintaining disease defences from experts across the pig sector.

How award-winning farm makes biosecurity a priority

The 2024 Overall Pig Producer of the Year, Crockway Farms, part of JMW Farms, has a number of disease prevention routines and facilities in place to protect herd health. The 3,400-sow indoor breeding unit, operating on a weekly system, sees biosecurity as a top priority for ensuring pig welfare and performance.

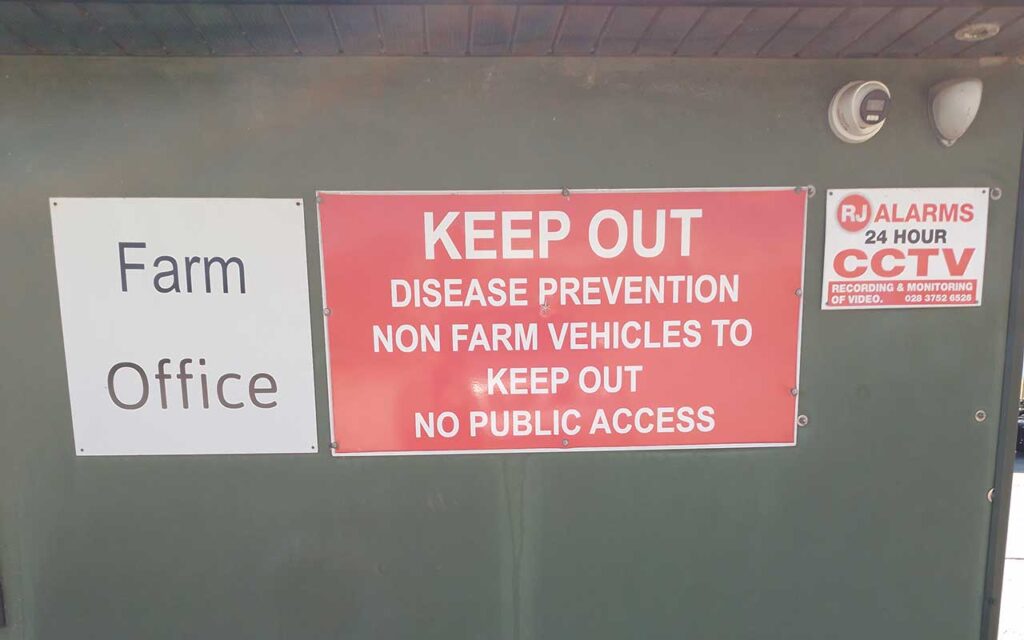

1. The main entrance has gates that are locked overnight and there is clear signage at several points, including by the weighbridge, where visitors are asked to stop and phone the office well before reaching the pig buildings. This is to help prevent the entrance of unknown or unauthorised vehicles and ensure all vehicles entering the site follow biosecurity protocols.

2. There is disinfectant and a knapsack sprayer kept at the weighbridge, readily available for all vehicles to use to disinfect wheels to minimise the risk of disease being introduced via vehicles coming onto the site.

3. The visitor policy requires all visitors to be 48 hours pig-free to avoid carrying pathogens between units and also to provide details of their last pig contact before signing the visitors book.

4. Security cameras are in place along the farm drive and on pig buildings, to alert managers to any unknown vehicles, so they can check whether they have a legitimate reason to be there and ensure they follow visitor protocols.

5. There are clean, spacious showers for all staff and visitors to use when entering and leaving the unit. Importantly, they have separate entrance and exit doors on either side of each shower, creating separate ‘dirty’ and ‘clean’ sides of the shower. Similarly, there are two sets of hooks, one before and one after the shower, for the two different sets of clothes worn off and on the unit.

6. There is a washing machine and tumble dryer, so all designated clothes worn on the unit by staff and visitors can be washed and do not leave the site, along with designated boots, which also stay on site. This includes boots and overalls provided for lorry drivers while they are on the unit.

7. Foot dips are placed at the entrance to the unit with covers to stop dilution from rainwater and clear signage to help remind people to use them.

8. Feed bins are sited near the unit perimeter, so feed delivery vehicles and feed mixer lorries do not need to go near the pig buildings. There is also a ‘red, amber, green’ system in place for JMW Farms’ lorries, which ensures that if a lorry has been to a unit positive for a disease, it can’t come to a unit that is negative.

Maximising biosecurity on an outdoor pig unit

Norfolk-based Richard Mellor, the 2024 Outdoor Pig Producer of the Year, has done a great deal on his pig unit to ensure good biosecurity.

1. Disinfecting vehicles, huts, equipment and wellies

Richard and his son-in-law, Sam Bilverstone, who makes them, have developed a portable disinfection station that is used for disinfecting vehicles that come onto the unit, and also for disinfecting huts and equipment.

The portable station runs solely off a water supply, with room for a 25-litre can inside the box, and operates without electricity. A variable doser unit mixes the disinfectant with the water within a range of 0.8-5.5%. The station also includes a 30m retractable and removable hose.

“The main yard has got one, and every entrance into the field has got one. You have to stop and do your wheels and dip your feet,” Richard said.

They have also made about 40 of the portable stations for BQP-Pilgrim’s Europe.

2. Long feed troughs

Richard noted that keeping pigs outdoors is more challenging because of the extra risk posed by birds and vermin.

“BQP took the initiative about 12 years ago to go with long feed troughs and individual feeders – on our units, everything is fed in long troughs in the group paddocks and individual feeders in the farrowing areas,” he said.

“Previously, we just used to put everything on the floor – you wouldn’t be able to see the pig unit for the number of birds if that was still the case. By using the long feed troughs, we are keeping feed off the floor, which stops vermin from reaching the feed. Birds are not good because they carry salmonella and E coli; if you have birds defecating everywhere, it’s not good for the pigs.”

3. Effective fencing

Good biosecurity is also about keeping the field well-fenced. “Although African swine fever is very infectious, they do say that with good biosecurity, you can keep it out of your unit,” Richard said.

“The main thing is effective perimeter fencing to keep wild animals out, especially if there are feral pigs around.

“We’ve got perimeter stock fencing all around the field at Grange Farm, because we haven’t really got any hedges. Warren Farm is in the middle of a 1,700-acre estate, so they don’t really need to stock-fence.

“We’re moving Warren Farm to near RAF Marham, and one of the fields is completely open, so we’re about to start stock-fencing all that in. As the crow flies, the two units will be about two-and-a-half miles apart – which is as close as we’d like to be.”

Time to review biosecurity plan

Livestock farms can minimise potential disease risks by having biosecurity protocols that can be implemented rapidly as required, given the serious disease threats lurking in Europe, according to Dan Clow from Neogen.

“Effective biosecurity requires a whole-farm approach, involving all members of the team in the identification and mitigation of risks to keep stock isolated from disease,” he said. “Farms should have written and clearly communicated protocols that are regularly reviewed and updated, and supported with good records.”

He suggested a comprehensive biosecurity programme should include:

- Control access to the facility: Access to the unit should be restricted and a defined secure perimeter established. Visitors should be limited to essential personnel, who must follow strict protocols for personal hygiene when entering and exiting the premises. Maintain a visitors log. Respect appropriate downtimes from previous livestock exposure.

- Vehicle biosecurity: Implement a programme to ensure all vehicles and any equipment entering and exiting the facility are cleaned and disinfected.

- Building biosecurity: Treat each building as a separate unit for better control. Clean and sanitise hands, disinfect footwear and change personal protective equipment between each building. Clean and disinfect all surfaces between groups of animals. Clean water systems and water and feed troughs.

- Control wildlife, dogs, cats, rodents and insects: Implement a pest management control programme to prevent potential vectors from transmitting disease.

- Educate and train personnel: Train all personnel in the implementation of the biosecurity programme to ensure consistent, high-level application.

Disinfection

Central to effective biosecurity is a strict approach to disinfection of everything and everyone coming onto the farm using a Defra-approved disinfectant.

Formulated to meet challenging farm conditions, Neogen Farm Fluid MAX is effective against foot-and-mouth disease at a 1:1,000 concentration (Defra test specification).

Neogen Viroxide Super, a general-purpose powder solution using oxidation chemistry, is effective against foot-and-mouth at a concentration of 1:1,300 (Defra test specification).

“I would advise farmers to review their biosecurity plans and ensure they have stocks of appropriate disinfectants to allow them to act, as required,” Dan concluded.

Developing an effective farm plan for the outer and inner rings

The spread of foot-and-mouth disease (FMD) and African swine fever in Europe should serve as a wake-up call to reinforce biosecurity measures, according to Nigel Bennet, Roam Technology’s livestock area manager for northern Europe. “Biosecurity risks are unique to each farm, so every biosecurity plan should be farm-specific,” he said.

He added that a strong biosecurity plan is based on four phases:

1. A farmer must continuously identify and assess the risks. These can be assessed on two different levels – the outer ring, external sources and the inner ring, the risks within the farm and its buildings.

2. A written biosecurity plan is the foundation of the biosecurity training programme.

3. It should be implemented and put into practice, with thorough training to ensure everything is done correctly by everyone.

4. Farmers should continuously monitor their plan and keep it up to date.

“The biggest risk and challenge comes from the outer ring, since this is harder to control. However, several measures can help mitigate these risks,” Nigel added.

“This includes keeping clothing, equipment, vehicles and animal housing clean. Monitoring farm access is equally important. Visitors can carry all kinds of diseases, so it is extremely important to carefully manage every visit.

“There should always be a copy of the biosecurity plan available for visitors. Making sure they stick to the protocol is an easy, but important step.

“To further reduce risk, new or returning animals must be quarantined for at least 21 days before joining the main herd. Rodents, birds and other wildlife should be monitored, as they can also spread diseases.

“The best way to protect a herd from incoming diseases is to stop it before it reaches the farm. At the same time, keeping the inner ring disease-free is just as critical. This can be achieved by providing clean watersources, regulating syringe use, defining specific zones in the farm and maintaining animal and personal hygiene.”

Disinfection

Roam Technology has been working in biosecurity for over 30 years and offers a wide range of cleaning, disinfection and performance products to help farmers strengthen their biosecurity protocols.

Its disinfectant, Huwa-San TR-50, is Defra-approved against FMD.